ELEY tenex is the world’s most consistently accurate .22LR cartridge.

With over 198 years of heritage and experience, engineering excellence is central to the success of ELEY tenex. Our highly skilled engineers combine state of the art machinery with high speed electronic visual inspection systems and Six Sigma methodologies to produce the cartridges that have redefined .22LR accuracy across the world.

The iconic flat nose projectile of ELEY tenex is one of many innovations pioneered by ELEY engineers. As it cuts through the air its revolutionary design pulls the centre of pressure forwards, aerodynamically stabilizing the projectile and increasing accuracy at the target.

Precise manufacturing techniques form cartridge cases of uniform length from a tightly controlled brass alloy. This ensures each propellant charge burns in a controlled volume, delivering consistent energy to each projectile.

Next, each cartridge is checked by a suite of analytical processes including computer controlled visual inspection and finely calibrated measuring equipment, all overseen by our extremely precise and meticulous engineers.

To achieve ultimate accuracy with ELEY tenex, a shooter should test their barrel. While ELEY tenex will offer unrivalled results as standard, matching the barrel and ammunition at our technical test ranges could make the crucial difference in a competition.

| Bullet Profile | Bullet Weight | Mean Velocity m/s | Mean velocity ft/s | Max Radial Standard Deviation | Lubricant | Cartridge Length | Ballistic Coefficient | Drag Model | Strike Depth | Recommended Head space |

|---|---|---|---|---|---|---|---|---|---|---|

| Flat-nose | 2.59 grams / 40 grains | 317m/s-330m/s | 1040ft/s-1085ft/s | 3.75mm | Beeswax-tallow | 25.4mm / 1 inch | 0.112 | RA4 | 0.012-0.015 in | 00.040-00.041 in |

Strike depth

The diagram below displays a cartridge case that has been shot. The indent, where the firing pin has hit the cartridge, is called a strike.

It is important to measure the strike depth on the cartridge because this is the point where the primer is activated.

A minimum strike depth is necessary to transmit sufficient energy to the primer to cause its ignition and ensure that the cartridge does not misfire.

The ideal strike depth for an ELEY cartridge is between 0.012–0.015 in. This depth can be measured using a strike depth gauge.

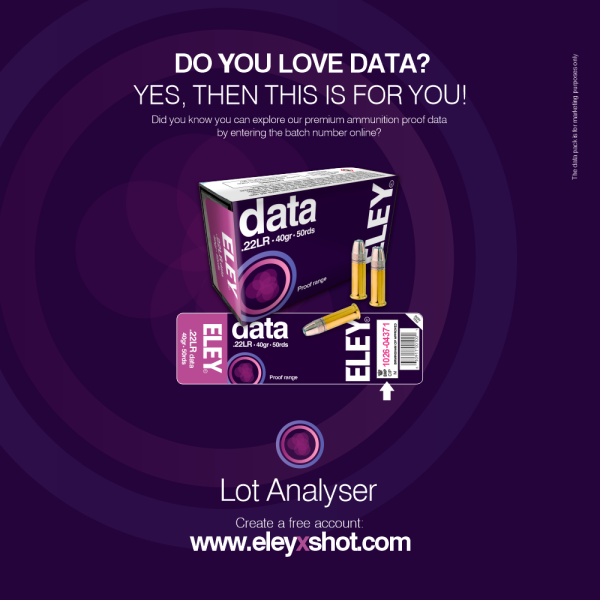

Batch numbers

Every box of ELEY ammunition has a specific number code printed on the end panel of the box.

The code relates to the grade of the product, manufacturing year, the loader on which it was produced, the batch number, and the average velocity of the ammunition across four barrels during the proofing process.

10 = Loaded product 26 = Year of manufacture 04 = Loader number 244 = Batch number for loader 1045 = Mean velocity across four barrels

If you love data, you can explore our premium ammunition proof data by entering the batch number online. Go to www.eleyxshot.com and create a free account.

ELEY vip – It’s all about you!

If you would like to discover how to achieve the ultimate performance with ELEY ammunition, visit www.eley.co.uk/vip It’s the quickest way to get the help you need.

Batch testing

Velocity and proofing

Cleaning you barrel

Understanding head space