How barrel rifling can help enhance your .22LR accuracy

Consistent accuracy is the Holy Grail for any target shooter. Accuracy is affected by a multitude of factors – and rifling is just one of them. With expertise in making precision small bore barrels, benchrest shooter Paul Tolvstad explains the different types of rifling and its impact on accuracy:

“First things first, what is rifling? Rifling is the arrangement of the grooves found on the inside surface of a rifle barrel. When fired, the helical grooves cause the bullet to spin so that it is more stable, improving both range and accuracy. Without rifling, the bullet will not spin and instead will act like a knuckleball thrown by a baseball pitcher… inaccurate!

There is a downside to rifling however, and that is that it must contact the bullet to create spin. This means that when the bullet leaves the barrel, the bullet surface is not smooth which creates drag. Thus making it easier for the wind to move the bullet around.

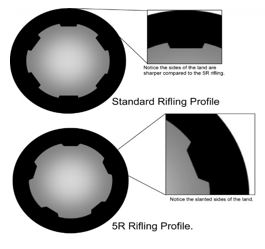

For many years, standard rifling was square and created sharp corners where it contacted the bullet. Barrel manufacturers then created different rifling patterns to help keep the bullet as smooth as possible. However, it is a trade-off between gripping the bullet enough to create spin while distorting the surface as little as possible.

This is the challenge for the world’s top benchrest barrel makers. They are always trying to find the balance between creating enough spin to make the bullet stable while minimising bullet distortion so that the wind won’t push it around everywhere.

The most commonly used barrels in rimfire benchrest include:

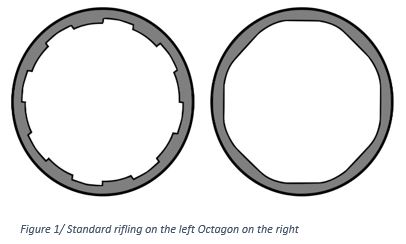

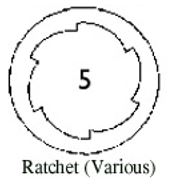

- Shilen: 4 groove ratchet, 8 groove octagon

- Muller Works: 5R, 4 and 8 minimally invasive (MI)

- Benchmark: 2 and 3 groove

- Broughton: 4 and 5 C’s

- Douglas: 4 groove

The Muller 4 and 8 groove barrels have a skinnier land with no sharp corners which is why they use the term minimally invasive. The Broughton 4 and 5C are very similar to the 5R rifling profile. Benchmark 2 and 3 groove and Douglas 4 groove have a standard square rifling pattern. Although the most dominant in benchrest arethe Shilen 4 groove ratchet and the Muller 4 MI, all have had success in big matches.”

This variation between rifling types is one reason why batch testing your ammunition is so beneficial for accuracy. ELEY’s test ranges worldwide are designed to eliminate variables and help find the right fit for the barrel, delivering repeatable performance shot after shot.

ELEY’s worldwide test ranges are in the UK, Germany, Norway, Canada and the US. Head to our test ranges page to contact our Customer Range Officers and book your visit.