ELEY has a rich Olympic history. Our world-renowned tenex cartridge made its Olympic debut in 1964 at the games hosted in Tokyo. Here, the premium cartridge won all the gold and silver medals on offer in the small-bore events. With the next games due to take place in Tokyo (although now at a postponed date in 2021), we’re reminiscing about what makes ELEY tenex so great.

Since its introduction, 13 Olympic cycles ago, ELEY tenex has helped athletes all over the world win 125 Olympic medals in shooting sport. Not to mention the hundreds earnt at various ISSF world cups and championships.

Our ammunition has helped crown six of the current world number ones…

- Seonaid McIntosh (GBR) – 50m 3P rifle women’s

- Petar Gorsa (CRO) – 50m 3P rifle men’s, 10m air rifle men’s

- Olena Kostevych (UKR) – 25m pistol women’s

- Zorana Arunovic (SRB) – 10m air pistol women’s

- Artem Chernousov (RUS) – 10m air pistol men’s

- Matt Skelhon (GBR) – R6 50m SH1, mixed 10m air rifle prone SH1

…and secure 48 quota places for the next Olympic games.

There are a lot of factors that go into the production of ELEY ammunition, and these have all developed as the years have gone on. But how do we make our .22LR ammo so accurate? Here are just some of the methods:

Control of materials

Unsurprisingly, it starts at the very beginning of the manufacturing process. The materials we source and use in our products are only the best. The lead, brass, powder and machinery are all of the highest quality.

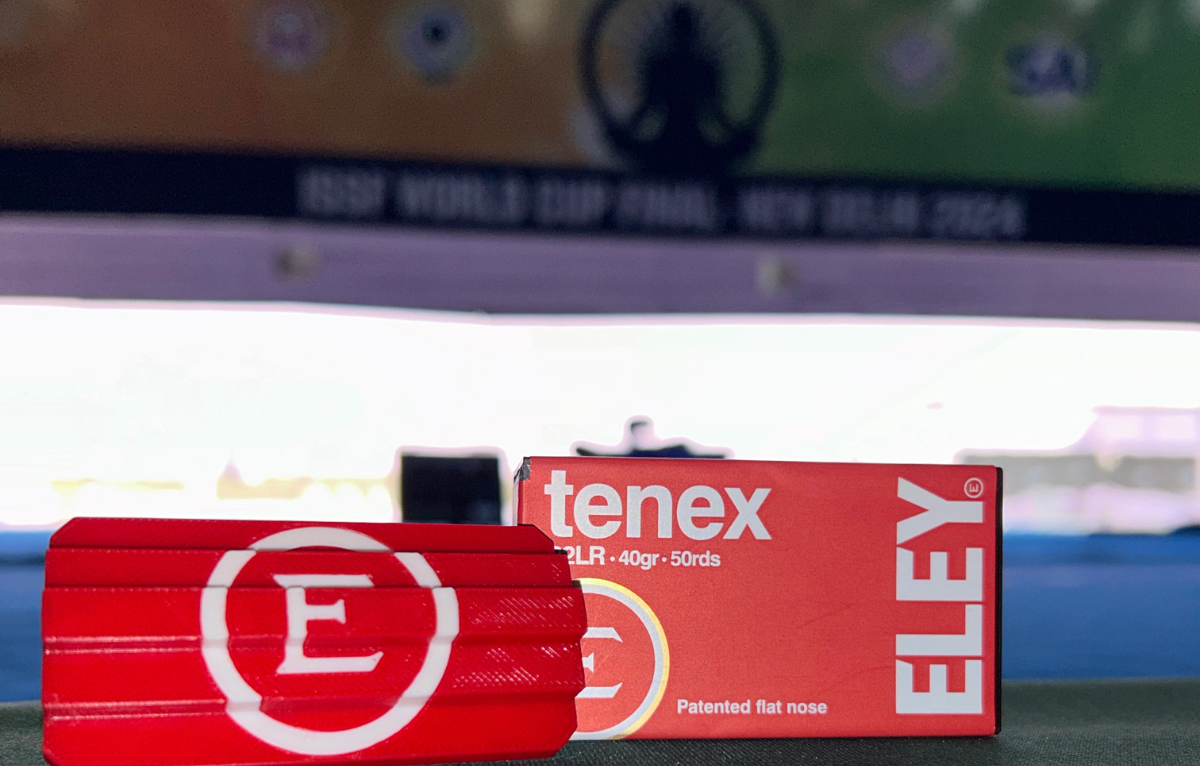

Flat-nose patent

The iconic flat nose projectile of ELEY tenex is one of many innovations pioneered by ELEY engineers. As it cuts through the air its revolutionary design pulls the centre of pressure forwards, aerodynamically stabilising the projectile and increasing accuracy at the target.

Small batch quantities

For our match-grade ammunition, ELEY only manufacture small lot quantities. This gives a greater level of control over the manufacturing process and allows our engineers to instantly spot and rectify anomalies.

These precise manufacturing techniques form cartridge cases of uniform length to a tightly controlled brass alloy, ensures each propellant charge burns in a controlled volume, delivering consistent energy to each projectile.

Independent testing

All tenex ammunition is subject to scrutiny from highly skilled engineers combined with state of the art machinery. A high speed electronic visual inspection system and Six Sigma methodologies produce the cartridges that have redefined .22LR accuracy.

Six sigma is a disciplined, statistical-based, data-driven approach to manufacturing and continuous improvement methodology eliminates defects in the product and process.

Just last year, ELEY’s independent testing set a new proof range record at ELEY HQ. This makes it officially the most accurate ammunition ELEY have ever manufactured.

When testing, ELEY uses four different barrels, each shooting five 10 shot groups.

The result? A mean radial shot diameter calculated at a fantastic 2.64mm. To calculate the RSD, it involves plotting the position of every shot fired on an x-y grid. As a result, this ensures all of the available data points from the shot group are used and is consistently quoted as the most accurate measurement for determining the tightest grouping load.

Packaging

ELEY developed a simple plastic box to store the match-grade ammunition in. The design keeps the rounds from touching each other and from bouncing the noses on the bottom of the box. This keeps a more true shape and ensures no damage can occur when travelling.

Batch testing

Ultimate accuracy comes from a range of factors, the shooters ability, the firearm and the ammunition. ELEY understand to win the three factors must have the best combination. ELEY manufacture world-class ammunition in a variety of batches and to achieve the ultimate performance we recommend using ELEY’s testing facilities.

Batch testing is designed to find the most accurate ELEY ammunition for your barrel to deliver results, records, and medals. During testing, 10 shots from each batch are fired through your barrel and the best performing batches are then shortlisted. A further 30 shots from those selections are fired until an overall 40 shot group size and consolidated score is recorded for each. The bespoke ELEY software makes analysing the results fast, simple and very accurate, helping you to find that record-breaking batch.

All the best athletes visit the ELEY test ranges to find that perfect batch.

Read why Austrian shooter, Thomas Mathis, always test his ammunition.

All of these factors go into producing Olympic grade ammunition. Just check out the most recent results!

Tenex’s medal winning success was at dominant at the 2019 ISSF World Cup Final in Putian, China. British rifle shooter, Seonaid McIntosh, put her trust in tenex to clinch the gold and world title in the 50m 3P rifle women’s final. Second place went to Ruijiao Pei (CHN) and third, Nina Christen (SUI). All three shooters in the final put their trust in ELEY tenex to secure a medal.

It was also three for three in the men’s event with all three shooters using ELEY tenex. Filip Nepejchal of Czech Republic struck gold and secured a new junior world record at the same time with a score of 462.9. Silver went to Serbia’s Milenko Sebic with 461.5 and Russia’s Sergey Kamenskiy rounded out the podium after recording a final score 449.8.

The tenex family is not only.22LR cartridges, but also includes competition air pellets. In 2018, ELEY launched its flagship air pellet – ELEY tenex air.

.177 calibre, 4.49/4.50/4.51 diameters, and 8.2 grains are the essential statistics that make up ELEY’s pellets. Delivering exceptional accuracy, 30% greater weight control than any competitor, and damage-resistant packaging, the proof is in its performance.

World number one’s Petar Gorsa, Artem Chernousov and Zorana Arunovic all use ELEY tenex air pellets.

If you’d like more information on ELEY, the tenex brand or any of our other ammunition offerings, please visit www.eley.co.uk. Alternatively, for the latest updates follow ELEY on social media @eley_ltd